ROLPIN LAMBRIS

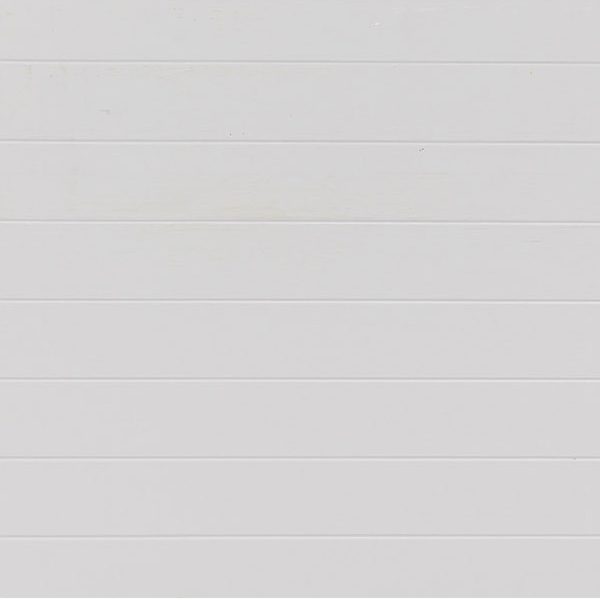

Rolpin LAMBRIS is a plywood made of MARITIME PINE (French origin) grooved on one side, like a wainscot. It has 2 long machined half-wood edges. PANELLING DECOR / TRADITION / PRIM

Format: 2500 x 600 mm. It is used for decorative dressing.

The Plus :

– Wide range of products for indoor and outdoor use under shelter (Prim)

– Quick and easy to install

Variants :

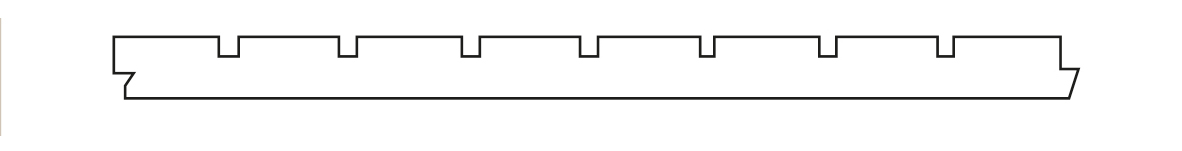

– LAMBRIS DECOR : U groove

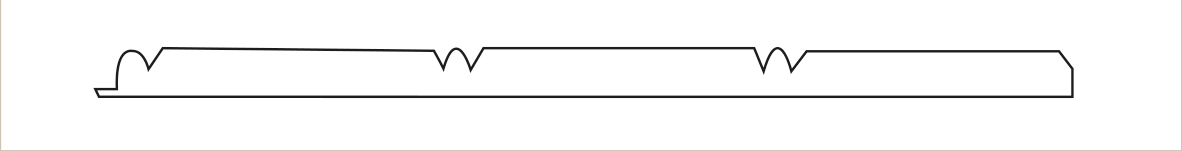

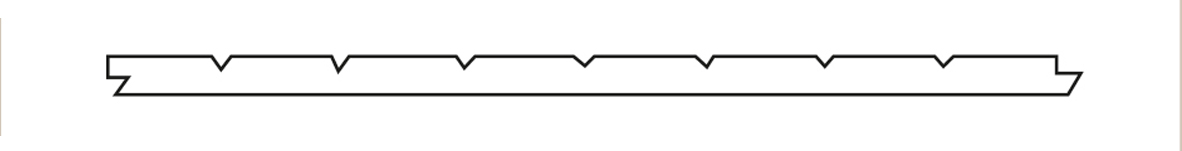

– TRADITION LAMBRIS : grooved “mouchette

– LAMBRIS PRIM : pre-painted white on one side

Where to find this product?

See the two sides above:

Product features

| Face | Closed face, without knots, with wood pellets (max 5 / m²). Occasional mastic repairs. U-shaped grooved face (width: 4mm, depth: 5mm, groove distance 75mm) |

| Counterface | Open face, not repaired, admitting knotholes and cracks |

| Finish | The 2 faces are sanded |

| LAMBRIS DECOR | U-groove |

| TRADITIONAL PANELLING | Grooved “mouchette |

| LAMBRIS PRIM | Pre-painted white on one side for quality of the sides |

| Dimensions | 2500 x 1250 mm (other formats on request) |

| Thicknesses | From 10 to 15 mm |

| Number of folds | From 5 to 7 |

| Packing | From 60 to 40 |

| Density | 560 to 610 kg/m3 |

| Uses | Decorative trim. |

| Collage | According to EN 314-2: bonding class 3 “outdoor environments”, water and weather resistant. Phenolic glue. |

| Options | Cutting and machining on request. |

| Non-structural construction jobs | System 2+ certificate of conformity according to EN 13986 + A1 |

| Outdoor environments | According to EN 636 + A1 (structural use). Approved to the French quality mark NF Extérieur CTBX and to the German mark BFU 100 DIN 68705 part 3. |

| Release of formaldehyde | Classification E1 According to EN 717.2 Formaldehyde emission measurements show a release of 0.02 mg/l of air according to the ISO 12460-4 desiccant method. This value is 15 times lower than the requirements of the Japanese standard F****, the most stringent in the world (0.3 mg/l) according to JIS A 1460 |

| Reaction to fire classification | According to EN 13501-1 + A1 Thickness > 9 mm : Euroclass D-s2, d0 |

| CE marking | 380 – CPD – 011 – EN 13986 + A1 |

Storage | It is advisable to store the packages in a dry place, preferably flat and level on dry rafters insulating them from the ground. The spacing between rafters is to be adapted to the thickness and nature of the stored panels. When storing in multiple stacks, align the rafters in height. On site, provide shelter or cover the panels with a waterproof but vapor permeable coating. |

Implementation | Comply with the rules of art, safety and the DTU in force – DTU 36.1. Comply with the rules of art, safety and the DTU in force – DTU. Preparation of the panels before installationApply in the workshop a protective primer, Fungicide, Anti-blue and Water repellent, on the face of the panels and on the edges. Check that the product used ensures the 3 functions and that it is suitable for use on plywood. Fungicide + water repellent products in organic solvent phase are recommended because they are more penetrating. Installation of the panelsLay the panels on cleats to ensure ventilation of the back surface, the cleats must be laid in staggered rows to allow air to circulate. If insulation is installed, adapt the thickness of the battens to allow for sufficient airflow between the insulation and the wainscoting to avoid humidity. FinishFor outdoor use or use in humid environments, ROLPIN LAMBRI plywood must be treated with a fungicide, anti-blue and waterproof primer and finished with opaque (paint) or semi-transparent or transparent (stain) finishes. MaintenanceFor outdoor use or use in a humid environment, ROLPIN LAMBRI panels require maintenance of the exposed visible side by applying a new coat of paint or stain. |

| Dimensional tolerances of the panels | They comply with the specifications of the EN 315 standard:

|

| Other features | Thermal conductivity Pentachlorophenol content λ = 0,13W/.K |

For more information and to consult the mechanical characteristics, download the data sheet available below.